The long and winding story of Newport Wafer Fab

The tale of Newport Wafer Fab is a parable for our times. It tells you everything you need to know about

- The UK's industrial strategy, or complete lack of it.

- UK's inability to decide what to do abt China.

- Most of all, UK's complete obliviousness to what our economy actually DOES

So while the following may seem like a deep dive into an obscure corner of our economy, we NEED to spend time thinking abt this stuff if we're serious about industrial strategy. But we're not. Govt has no semiconductor strategy. No plan here. It's not even clear who's in charge.

Anyway, Newport Wafer Fab. You’ve prob heard abt it. Was recently taken over by Nexperia, Chinese-owned company based in Netherlands. Now @KwasiKwarteng is pondering whether to cancel the takeover on national security grounds. It’s a big deal. But there are big misconceptions.

The chips they make here are prob not the thing u immediately think of when u think of silicon chips. It’s NOT the super complex “brain” chip that helps yr smartphone or computer think. Instead, they make something less sexy but just as, if not even more, important: POWER SILICON.

Power silicon is the kind of ugly sister of the semiconductor world. These are small pieces of silicon (actually sometimes quite large but we’ll get to that) which do a very simple but incredibly important function in all electronics: passing current from one bit to another…

That’s right: any electronic device has one (actually usually loads) of these little bits of silicon in them. Your charging cable for your phone has one at the very end of it as a surge protector - and others besides that. POWER SILICON IS EVERYWHERE.

When u push the brake pedal of yr car, it isn’t mechanically connected with brake pads (well, not in a modern car). It sends an electrical signal via POWER SILICON to yr brakes. Same thing when you open yr electric windows, turn on lights, change side mirrors etc. POWER SILICON.

Of the 250 or so semiconductors in a new car, the VAST majority are POWER semiconductors. The recent semiconductor shortage has been across the board - but it’s striking that most people have lumped the chips all together - as if every silicon chip does the same job. They DON’T

As I say, power silicon is not sexy. It’s not like the sexy chips TSMC makes in Taiwan, with transistors measured in nanometres. There, the goal is to fit as many transistors in as small a space as possible. The techniques they use to do that are truly mind-blowing.

In power silicon the objective’s different. It’s abt quality not quantity. It’s abt making a transistor that’s incredibly robust, capable of transferring electric current as efficiently as poss. There’s a real skill to doing this well. & it turns out Newport is pretty good at it!

The reason I’m banging on abt this is because this distinction seems to have been entirely omitted from most of the coverage of this saga. Most reports (see this recent BBC story) imply Newport’s a bit rubbish vs Taiwanese companies like TSMC. But it’s NOT the same thing!

Comparing power semiconductors & the kind of logic semiconductors Intel/TSMC make is apples vs pears. It's like saying: this rugby player is rubbish because he's no good at football. They. Are. Different. Things. And Newport happens to be a WORLD leader in making power silicon.

I visited the factory recently. Feels a bit like a spaceship. Plants like these are called “ballroom fabs”, amazing structures with foundations drilled into the bedrock to minimise vibration from anything (planes, cars, heavy machinery). Because these machines are ultra-precise.

The entire chip-making floor is suspended above another floor called the "sub-fab" where all the gases are piped in (chip-making machines need a LOT of exotic gases). Here we are in the sub-fab...

The reason the fab lights are orange/yellow is because they use a process called photolithography to etch the circuitry on the silicon wafers, which in turn means they’re v light sensitive. White light could damage the chips.

Reason everyone is dressed in hazmat suits is because this is a “clean room” - 1000 times cleaner than an operating theatre. Why? Because a speck of dust will destroy a silicon chip. As with the lights - everything is done here to maximise precision and minimise interference.

This comes back to one of the most important things you need to know about semiconductor manufacturing. The mark of a great fab is not just its ability to etch sophisticated patterns on a chip but its consistency - its yield.

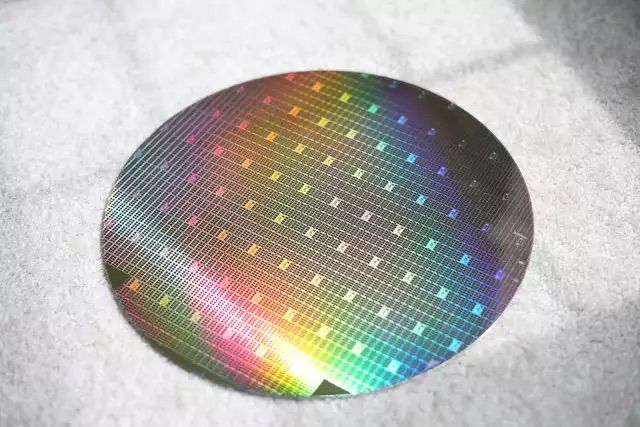

This is a silicon wafer. On it are hundreds of tiny identical squares, etched with transistors. These squares are the chips. You slice it up later. Point is, fabs are judged on what % of faulty chips they have on avg per wafer. Newport's yield is consistently 95% plus

In short they're really good at making these power chips. Acc to Malcolm Penn, one of the world's leading semiconductor experts, Newport had chip making knowhow Nexperia lacked. He suspects they'll use that in their new fab they're building in China.

That brings us to the broader international picture. There is a global race between China and the rest in semiconductors. But while Chinese firms are struggling to compete with TSMC on logic chips (those brains), as we know by now, that's not the only type of semiconductor.

This matters because while power silicon is not traditionally v sexy, the rise of electric cars makes it a bit sexier. Better power semis in an electric car's inverter can boost its range. And there's a new type of power semi which could change everything: compound semiconductors.

Compound semiconductrors are made of compounds other than silicon: gallium arsenide or silicon nitride. They can be much more efficient than silicon. This is the v cutting edge of power silicon. Tesla is using SiC in some of its newest cars' invertors.

Another interesting area is photonics - a new field where you're using light rather than electricity on silicon wafers. This field promises major leaps in computing - not to mention new applications like incredibly advanced sensors. It’s quite exciting!

One of the world's leaders in this new field is Rockley Photonics. This UK firm is designing new health sensors which, it's rumoured, may go into future Apple Watches. And guess where they were planning to manufacture their chips? That's right: Newport.

Up until the takeover Newport was a “foundry” - a chip facility where anyone could make their chips. But now it’s been taken over by Nexperia, it will only make Nexperia chips. That means no compound semiconductors and no photonics chips like those Rockley designs…

Now, one can argue whether it matters that we MAKE chips in the UK. But few in Govt are even AWARE we have a genuinely important silicon plant. Like everyone else, they lump Newport in the same basket as TSMC instead of noting it’s in a different field where it’s quite a big deal.

That brings us to the broader issue. UK doesn’t have a semiconductor strategy. @DCMS has been charged with putting one together but no sign of anything. It’s not clear they’ve understood the nuances here. And anyway it’s @beisgovuk who will decide on Newport’s fate. It’s a mess.

There's a lazy assumption in Whitehall that the only expertise the UK has in semiconductors is in the kind of thing Arm does - chip design tools. And there’s no doubt Arm is a world leader. But it turns out the UK has deep expertise in power silicon and, increasingly, compounds.

But even here things aren’t as simple as they seem from the outside. Because when I visited Newport the other week they said actually their compound semi facilities are far LESS advanced than some suggest. This is their supposedly leading edge compound fab. It’s an empty room.

They argue the takeover is the best thing that's happened to the site in years. After years without pay rises or investment, finally the site and its employees are getting an influx of cash. New machines are being installed. Everyone is happier than they have been for ages…

So this is not simple. Newport was struggling as a foundry. It's now in better financial shape. But there's a real chance, say industry experts, that a lot of UK expertise will now leak to China. And we may fall back in the compound semiconductor race. Is this a problem?

Short answer is: no-one in govt has the foggiest. Despite all this talk about industrial strategy there is ZERO strategy here. And in a high-capital investment sector like semiconductors that's a big deal. You often NEED strategy & support if you’re going to compete vs Taiwan etc

A good example is ASML. For years this Dutch firm making lithography tools for semi manufacture, was a money sink. Many wondered whether it would EVER make profits. Today it is a money machine w/ an effective monopoly on the machines TSMC use to make chips.

There would be no ASML had the Dutch not had a long-term strategy. But UK has NO semiconductor strategy. It doesn't even grasp what they do in Newport & how it differs from logic chip manufacture. Anyway, much more on this in my long read.

Oh and if you want to see me wearing a head-to-toe hazmat suit, which is clearly why you read to the end, here’s the report we just aired on @skynews about this. Ongoing story, so more to come from us on this in the coming months.

Comments ()